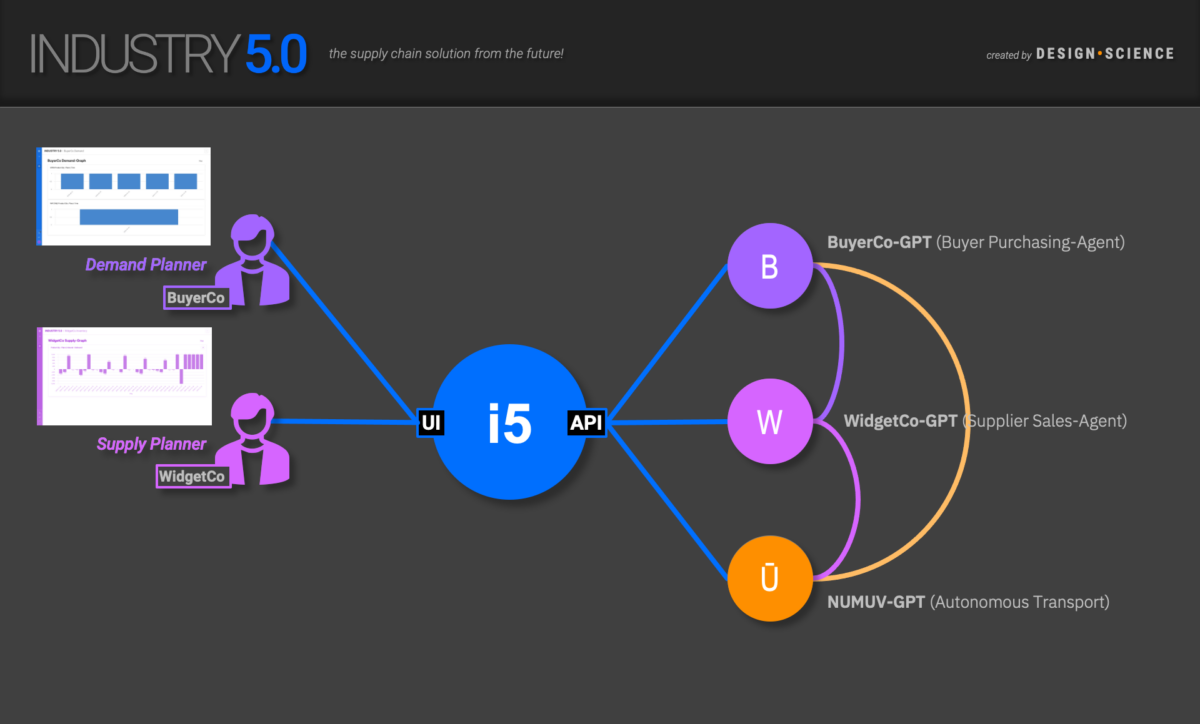

NOTE: this example lesson / game-plan was generated by INDUSTRY 5.0Two teams within a company will compete in a turn-based simulation to optimize the demand-supply network over a multi-year period.

Your company’s i5 Admin may act as a ‘Facilitator’ for innovation and experimentation activities by constructing various scenarios with unexpected disruptions.

The game will be facilitated by an instructor who introduces variability and volatility events. The winning team will be the one that achieves the best comprehensive design and demonstrates superior anticipatory skills.

Game Setup

| Team A | Focused on efficiency and cost reduction. |

| Team B | Focused on sustainability and resilience. |

| Facilitator | Configures and introduces unexpected events (environmental, political, economic changes). |

| Game Rounds | Each round represents a multi-month period, resulting in multiple rounds over a multi-year period. |

Initial Setup

| Baseline Data | Current state of the supply chain network (inventory levels, supplier contracts, logistics providers, market conditions). Initial KPIs (efficiency, sustainability, resilience metrics). |

| Objectives | Improve overall supply chain performance. Anticipate and respond to unexpected events. Balance efficiency, sustainability, and resilience. |

Round 1: Initial Assessment and Strategy

| Team A: | Analyze current inventory levels and supplier performance. Identify cost-saving opportunities – e.g., renegotiate supplier contracts, optimize logistics routes |

| Team B: | Assess sustainability practices of suppliers and logistics providers. Develop plans to improve resilience. – e.g., diversify suppliers, invest in renewable energy sources |

| Facilitator: | THEN, BEFORE NEXT ROUND – INTRODUCES AN UPCOMING ENVIRONMENTAL REGULATION CHANGE THAT WILL TAKE EFFECT IN 12 MONTHS. |

Round 2: Implementing Initial Strategies

| Team A: | Renegotiate contracts with key suppliers to secure lower prices. Implement a new inventory management system to reduce holding costs. |

| Team B: | Begin transitioning to suppliers with better sustainability practices. Invest in renewable energy projects for key facilities. |

| Facilitator: | ANNOUNCES AN UNEXPECTED SURGE IN DEMAND DUE TO A NEW MARKET TREND. TEAMS MUST ADJUST THEIR STRATEGIES ACCORDINGLY. |

Round 3: Responding to Demand Surge

| Team A: | Increase production capacity to meet the surge in demand. Expedite shipping schedules with logistics providers. |

| Team B: | Scale up production sustainably, ensuring minimal environmental impact. Strengthen partnerships with logistics providers to ensure timely delivery. |

| Facilitator: | INTRODUCES A GEOPOLITICAL EVENT THAT DISRUPTS SUPPLY CHAINS IN A KEY REGION. |

Round 4: Managing Geopolitical Disruption

| Team A: | Identify alternative suppliers to mitigate the impact of the disruption. •Increase safety stock levels to buffer against supply chain uncertainties. |

| Team B: | Evaluate the resilience of current suppliers and logistics routes. •Implement contingency plans for supply chain continuity. |

| Facilitator: | ANNOUNCES AN ECONOMIC DOWNTURN THAT AFFECTS CONSUMER SPENDING. |

Round 5: Adapting to Economic Downturn

| Team A: | Adjust production schedules to align with reduced demand. Implement cost-cutting policies across the supply chain. |

| Team B: | Focus on maintaining sustainability initiatives while managing costs. Explore new markets to offset the decline in consumer spending. |

Evaluation and Scoring

| Winner Announcement: | The facilitator announces the winning team, highlighting their strategies and how they effectively anticipated and managed unexpected events. |

| Debrief: | Teams discuss their approaches, what worked well, and areas for improvement. The facilitator provides feedback and insights into how the game mirrored real-world supply chain challenges and opportunities. |

Conclusion

| Metrics: | Efficiency: Cost savings, inventory turnover, order fulfillment cycle time. Sustainability: Carbon footprint, energy consumption, waste reduction. Resilience: Supplier risk score, logistics risk score, ability to recover from disruptions. |

| Final Scores: | Each team’s performance is assessed based on the metrics, and points are awarded accordingly. The team with the highest overall score wins, demonstrating the best comprehensive design and anticipatory skills. |

By following this step-by-step approach, INDUSTRY 5.0 by Design-Science provides a dynamic and engaging way for participants to develop and apply advanced supply chain management strategies, leveraging both predictive analytics and real-time decision-making.