CONCEPT PAPER

Robb Bush | Chief Architect & Designer Design-Science | https://design-science.co

1. OBJECTIVE: Breakthrough Capability

The NUMUV system proposes a paradigm shift in transportation: the truly autonomous movement of people and cargo – transparently, efficiently, comfortably, predictably, and safely.

Unlike incremental advances in “driverless cars” or electrified vehicles, NUMUV is a system-level redesign of mobility and logistics. Just as the horseless carriage was more than a horse replacement, NUMUV breaks with the paradigm of the “vehicle” as the core unit. Instead, it introduces:

- Pods: standardized, fractal-dimension units designed for both people and goods. Pods are decoupled from the conveyance platform, enabling modularity, customizability, and cross-modal interoperability.

- Transporters: a family of autonomous platforms across land, water, air, subterranean, and orbital modes, capable of moving pods seamlessly between hubs.

- Transfers: robotic, automated pod handoffs at nodes and hubs, removing today’s “value leaks” in time, cost, and inefficiency at modal boundaries.

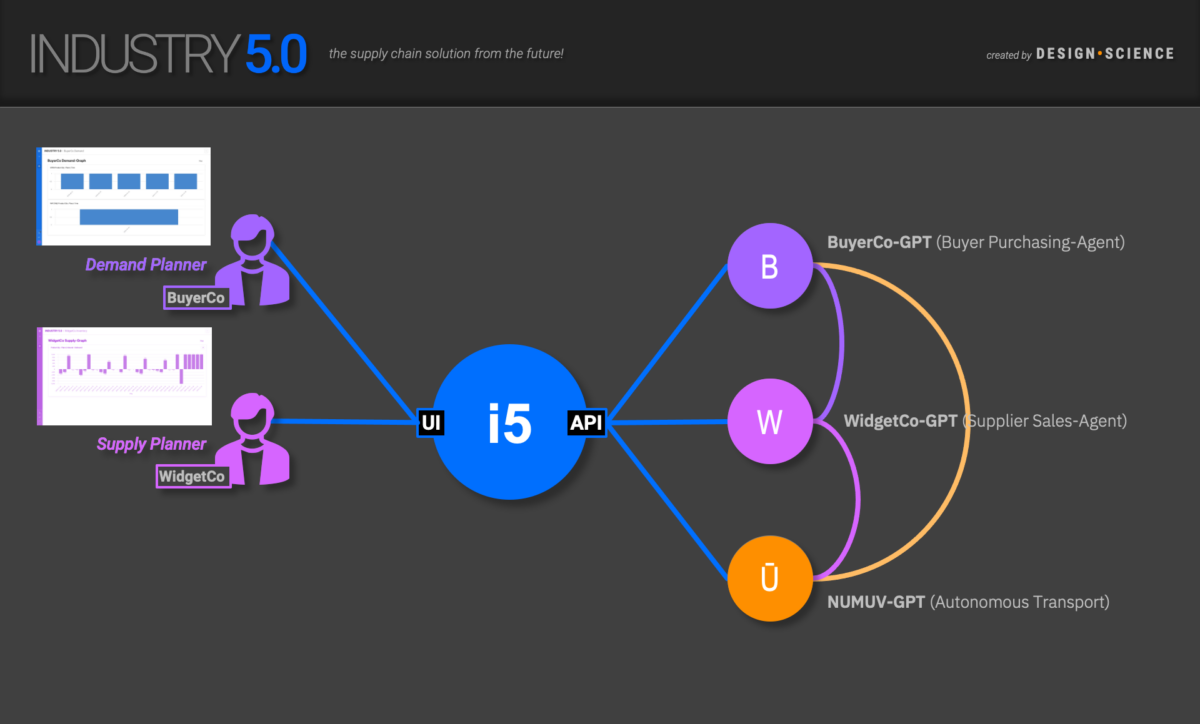

- Orchestration: the i5 agent-based coordination engine, which employs transactional grammar, temporal logic, and dynamic coordination graphs to match supply and demand for people, products, and services in real time.

The Job to Be Done is clear:

By 2050, global transport activity will increase by a factor of two to three. NUMUV is designed to deliver this additional capacity without tripling infrastructure, congestion, or emissions.

Breakthrough Capability:

NUMUV creates a modular, universal system that treats transport as a physical-internet, dynamically routing pods across multiple conveyances. It offers a radical improvement in throughput and efficiency, with simulation evidence showing potential for 30–50% reduction in transfer costs and times and 20–40% increase in load utilization. Importantly, the framework is future-proof, adaptable to disconnected environments, disaster response, and even orbital logistics. NUMUV therefore addresses not just what moves, but how the world moves, offering a reimagined transport system capable of meeting 2050’s demands while enhancing efficiency, resilience, and sustainability.

- NUMUV (pronounced “new-move”): A Modular Transport and Logistics System designed by Robb Bush of Design-Science, focused on the truly autonomous movement of people and cargo – transparently, efficiently, comfortably, predictably, and safely. NUMUV introduces modular pods, universal connectors, and multi-modal transporters to create a physical-internet for mobility.

- i5 (short for “INDUSTRY 5”): An AI-Agent Orchestration System developed by INDUSTRY 5, Inc. (also created by Robb Bush & Design-Science). i5 provides the orchestration intelligence behind NUMUV, using agent-based coordination, transactional grammar, and temporal logic to enable resilient, real-time optimization across multiple transport modes. If every aspiring autonomous vehicle-maker today creates their own orchestration OS without a global-standard, no progress, only more complication.

2. STATE OF THE PRACTICE: Why Today’s Systems Fall Short

Today’s transportation and logistics systems are mode-siloed, vehicle-centric, and incrementally improved rather than fundamentally re-imagined. Despite advances in electrification, automation, and connectivity, the overall architecture has remained largely unchanged since the mid-20th century.

Mode Silos and Transfer Inefficiency

Each mode—road, rail, marine, air, and space—operates with its own incompatible standards, containers, and transfer points. Intermodal transfers are the largest “value leaks”, consuming time, labor, and cost without adding value. ISO containerization in the 1960s solved a similar challenge for bulk freight; however, today’s systems lack a universal standard for human-scale pods that can enable seamless transfers.

Vehicle-Centric Innovation

Current approaches center on making smarter or cleaner vehicles (driverless cars, electric trucks, autonomous drones). This “horseless carriage problem” produces incremental gains but compounds complexity: more vehicles, each optimized for a single mode, but without addressing the system-level bottlenecks. As a result, congestion and inefficiency worsen despite billions invested.

Centralized Logistics Fragility

Enterprise Resource Planning (ERP) and Transportation Management Systems (TMS) rely on centralized planning and constant connectivity. Such systems are brittle in the face of disruptions (natural disasters, cyberattacks, supply shocks) because they cannot adapt dynamically when disconnected. They also optimize within silos—a trucking TMS does not dynamically coordinate with rail, air, or marine networks in real time.

Metrics of Inefficiency

- Load Utilization: U.S. trucks average only ~60% load factors; containers often return empty.

- Congestion Costs: Estimated at >$120 billion annually in lost productivity, wasted fuel, and delays.

- Carbon Waste: Empty backhauls and inefficient transfers contribute significantly to CO₂ emissions.

- Lack of Reverse Logistics Integration: Today’s systems are optimized for outbound flows, not circular or reverse supply chains.

Summary:

The state of the practice is defined by fragmentation, inefficiency, and fragility. Each innovation layer—apps, electrification, autonomy—adds complexity to vehicles or operators, but the system as a whole remains constrained. Without a breakthrough in modular interoperability and orchestration, today’s trajectory cannot scale to handle the 2–3× increase in demand expected by 2050.

3. OPPORTUNITY: Why Now?

The world faces a converging set of pressures that make a paradigm shift in transport not only possible, but necessary. NUMUV is uniquely positioned at the intersection of rising demand, advancing technology, and supportive policy momentum.

Exponential Growth in Demand

- Global: OECD/ITF projects transport activity to nearly triple by 2050 in both passenger-kilometers and freight tonne-kilometers.

- U.S.: The U.S. DOT’s Freight Analysis Framework (FAF5) projects freight tonnage to grow by ~50% and freight value to double by 2050.

- Urbanization: UN DESA forecasts the world’s urban population share to rise from ~55% today to ~68% by 2050, adding demand pressure on urban networks.

- Aviation as Bellwether: Airports Council International projects global passenger traffic to more than double to 22.3 billion by 2053, underscoring long-term upward pressure on mobility.

Technological Enablers

- Multi-Agent Orchestration (i5): Advances in agent-based AI, transactional grammar, and dynamic coordination graphs enable distributed, resilient, real-time optimization across disconnected and heterogeneous networks.

- Digital Twins & Simulation: The INDUSTRY 5.0 engine already powers NUMUV simulations that demonstrate time and cost savings while freeing up existing capacity.

- Manufacturing Advances: Additive manufacturing and modular assembly allow rapid local production of pods and connectors, reducing entry barriers.

- Universal Connectors (NPCI): Analogous to the ISO container revolution of the 1960s, NUMUV’s Pod Connector Interface provides physical and digital interoperability across every mode of transport.

Policy & Strategic Alignment

- Resilience Mandate: U.S. DOT and ARPA-I emphasize resilience, safety, and efficiency in infrastructure – NUMUV directly delivers on these mission goals.

- Sustainability Pressures: Climate goals demand CO₂ reductions even as transport volumes grow. NUMUV’s reverse-first logistics and improved utilization offer a practical mitigation path.

- National Competitiveness: Leadership in autonomous, modular, cross-modal logistics positions the U.S. to define the next global standard – much like containerization once did.

Why Now?

The last disruptive transport redesign – containerization – occurred over 60 years ago. Today, the convergence of exponential demand, AI-enabled orchestration, and modular manufacturing makes NUMUV’s breakthrough both technically feasible and urgently necessary.

4. IMPACT: What Difference Will It Make?

If successful, NUMUV will deliver a step-change in transport and logistics capacity, efficiency, sustainability, and resilience – while unlocking a new layer of national competitiveness in infrastructure and innovation.

Capacity Without Congestion

NUMUV enables the U.S. and global systems to handle 2–3× more people and goods by 2050 without tripling vehicles, infrastructure, or costs. By coupling NUMUV’s modular physical system with i5 orchestration intelligence, demand for people, products, and services can be matched to supply dynamically across all modes. Mobility is no longer constrained by mode silos; pods flow through a physical-internet, orchestrated in real time.

Efficiency Gains

Robotic pod transfers and NPCI connectors reduce transfer frictions by 30–50%, eliminating today’s modal bottlenecks. Orchestration and reverse logistics integration increase vehicle and container utilization by 20–40%, cutting empty miles and wasted capacity. i5 provides a measurement framework that ensures transport resources are allocated to the highest-value flows in real time – not only for freight but also for passengers and services.

Sustainability & Climate Alignment

NUMUV reduces empty returns through reverse-first logistics, directly lowering CO₂ emissions. System efficiency improvements allow more throughput with fewer trips, complementing electrification and alternative fuels. NUMUV thus provides an operational lever for climate goals, ensuring that demand-side efficiency matches supply-side energy transitions.

Resilience in Any Environment

NUMUV pods and decentralized orchestration ensure continuity of supply chains even when central systems are disrupted. i5 is designed for delay-tolerant, decentralized environments, enabling logistics in rural, remote, or disconnected settings. The same modular pods and orchestration principles can extend to orbital logistics, off-planet manufacturing, and lunar/Mars networks.

Economic & Societal Value

NUMUV creates “innovation space” for U.S. companies to design pod interiors, services, and conveyance platforms – just as the shipping container catalyzed new industries in global trade. For people, i5 optimizes personal mobility, ensuring that individuals are in the right place, at the right time, with comfort and predictability. For goods, i5 ensures just-in-time delivery of products and services, reducing waste and cost. Pods with standardized custody logging and zero-trust security layers improve safety for both passengers and cargo.

Transformational Difference

Together, NUMUV and i5 move beyond the “vehicle paradigm” into a new mobility architecture, where demand is continuously orchestrated with supply, and transport is measured as part of a greater Demand : Supply : Move ecosystem. This is the breakthrough needed to transform transportation into a resilient, efficient, and scalable backbone of the 21st century economy.

5. PLAN: How Do We Execute?

NUMUV’s development pathway is designed to demonstrate feasibility quickly, while building momentum toward full-scale deployment. The roadmap combines simulation, prototyping, pilot deployments, and open standards adoption, ensuring that progress is both measurable and scalable.

Phase 1: Simulation & Standards (Years 1–2)

- Simulation Validation: Use the INDUSTRY 5 engine to model throughput, cost, and CO₂ savings of NUMUV + i5 at national and regional scales. Benchmark against U.S. DOT data (FAF, BTS).

- Standards Development: Publish the NUMUV Pod Connector Interface (NPCI) as an open standard, modeled on the success of ISO containerization. Engage modal agencies and industry consortia to ensure adoption.

- Outcome: Credible evidence package for feasibility and alignment with DOT’s resilience and sustainability priorities.

Phase 2: Prototypes & Controlled Pilots (Years 2–3)

- Prototypes: Build modular pods (cargo and passenger) and robotic transfer stations.

- Testbeds: Pilot in urban corridors, campuses, and disaster-response hubs.

- Metrics: Demonstrate 30–50% transfer savings and 20–40% utilization gains in live settings.

Phase 3: Multi-Modal Pilots (Years 3–5)

- Integration: Connect pods across road, rail, marine, and air hubs.

- i5 Deployment: Operate agent-based orchestration in live corridors.

- Focus: Reverse-first logistics, resilience, and user acceptance.

- Stakeholders: Logistics operators, OEMs, municipal transit authorities, state DOTs.

Phase 4: Scale & Expansion (Years 5–7)

- Nationwide Deployment: Extend NUMUV + i5 across national freight corridors and commuter networks.

- Legacy Integration: Middleware APIs for compatibility with existing ERP/TMS.

- Off-Earth Demonstrations: Begin orbital/lunar pilots with NASA/DoD.

Resources & Partnerships

- Funding: $20–50M staged investment over 5–7 years.

- Partnerships: U.S. DOT modal agencies (FHWA, FRA, MARAD, FAA), NASA/DoD, logistics operators, OEMs, municipalities.

- Ecosystem: Open innovation approach allows companies to innovate pod interiors, services, and conveyance platforms.

Risk Identification & Mitigation

- Adoption Risk: Mitigated by open standards and modular design.

- Integration Risk: Addressed with adapters and APIs.

- Public Acceptance: Managed through phased, transparent demonstrations.

- Policy Alignment: Continuous engagement with DOT and ARPA-I.

Summary:

By following a progressive path from simulation → prototypes → pilots → national scale, NUMUV demonstrates feasibility quickly, delivers measurable impact early, and provides a credible trajectory toward transformational deployment.

References

- Bush, Robb (2025). Modular Transport and Logistics System Using Interoperable Pods, Universal Docking Interfaces, Agent-Based Orchestration, and Adaptive Transfer Infrastructure. U.S. Provisional Patent Application #63/816,350.

- Bush, Robb (2025). Systems and Methods for Agent-Based Orchestration (i5). INDUSTRY 5, Inc. Provisional Patent Application #63/812,498.

- OECD/ITF (2023). Transport Outlook 2023. Organisation for Economic Co-operation and Development / International Transport Forum.

- U.S. Department of Transportation, Bureau of Transportation Statistics (2023). Freight Analysis Framework (FAF5).

- United Nations, Department of Economic and Social Affairs (2019). World Urbanization Prospects: The 2018 Revision.

- Airports Council International (2024). World Airport Traffic Forecasts 2024–2053.

- Federal Highway Administration (2022). Traffic Congestion and Reliability Trends and Statistics. U.S. DOT.

- International Energy Agency (2023). World Energy Outlook 2023 – Transport Sector Analysis.

- Bush, Robb (2024). NUMUV: Modular Transport and Logistics System – Concept & Design Hypothesis. Design-Science LLC.

- Bush, Robb (2020). NŪMŪV Project Launch. Design-Science LLC, Dec 29, 2020.

Marks the early articulation of NUMUV as an experimental multi-modal mobility and logistics system in December 2020. - Bush, Robb (2023). NUMUV: What Is It and Who Cares? Design-Science LLC, Mar 20, 2023.

Explores the societal, economic, and innovation impacts of NUMUV. - Bush, Robb (2024). NUMUV Project Summary. Design-Science LLC, Aug 8, 2024.

Provides the formal Design Hypothesis: “By 2050, how can the world move 3× more people and cargo…?” - Bush, Robb (2004). Review: Going Conference 2004. Sep 15, 2004.

Early reflections on mobility paradigms; seeds of NUMUV’s system-level design approach. - Sturges, Dan (2023). Near to Far: Designing Equitable and Sustainable Transportation for Communities. Amazon Publishing.

Transportation visionary and NUMUV inspiration; co-creator of neighborhood EVs (NEV/GEM Car), contributor to Ford Th!nk and Wired magazine’s coverage of mobility futures. - Lutz, Bob (2017). Kiss the Good Times Goodbye. Automotive News, Nov. 6, 2017.

Editorial by a veteran auto executive arguing for the rise of standardized autonomous travel modules and the obsolescence of human driving