ONE Network 3D WMS Game Development

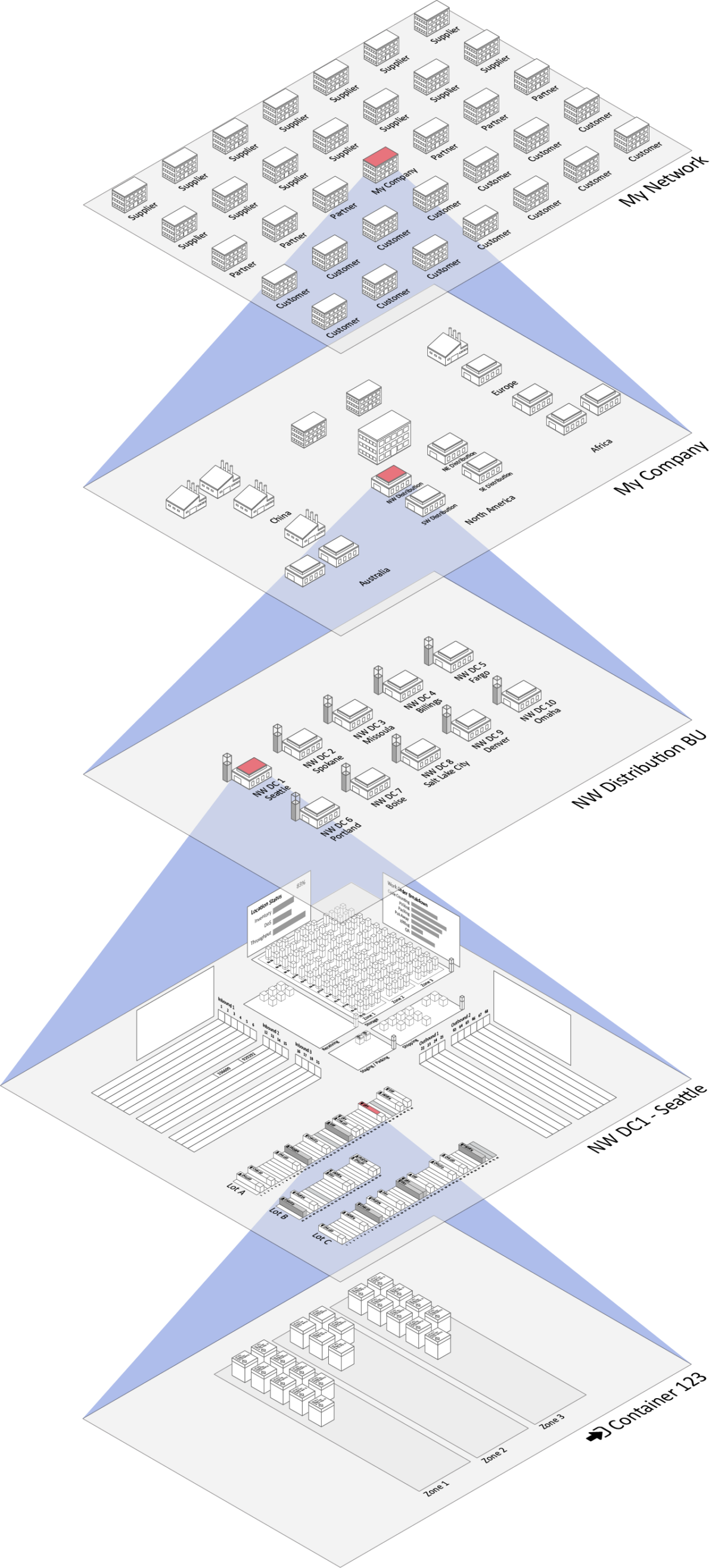

NAVIGATION – GETTING AROUND

– Between Levels

– Between Sites

– Assets

– Within Charts

OBJECTS (3D Models)

– All are Data-Driven to change shape (dimensions), color, or location (time & space)

– Sites / Buildings

– Physical Assets (containers, assembly lines, material, vehicles)

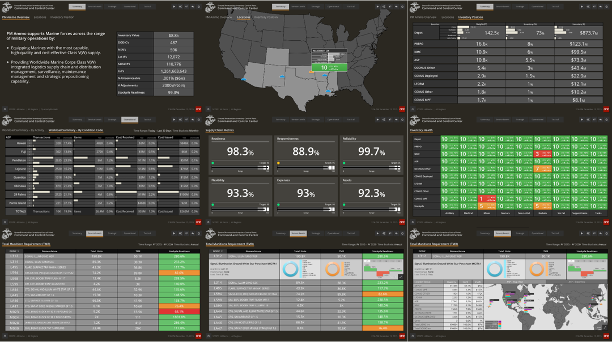

– Charts / Analytics

LEVELS

– Network Level View

– Corporate Level View

– LoB Domain Level View (My Locations)

– Site / Inside View

– Warehouse

3D Warehouse Mgmt

Show “Virtual Buffers” in 3D Warehouse

– Receiving

– QA

– Storage

– Staging

Drag and Drop from Storage to Staging (creates a pick-list)

“Level 6 Data” Where is it, what asset, how many, what order

GENERAL NAVIGATION

Navigation from Corp Level

from Inbound Docks / Yard

to

Warehouse (move something from Storage to Staging)

to

Outbound Docks / Yard

– Ability to show resources form multiple locations in a single view

Asset View

GAME MECHANICS

– Purpose / Objective for Player

– Gain Points, Health, Badges, Unlock New Features / Levels

MULTI-PLAYER COLLABORATION

OVERALL SCENE

– Add Timeline to Lanes

– Navigator Menu – Jump to Top View, Side View, Reset View

– Zoom In Out (Stay in Isometric mode)

– Drill Down from a Higher Level to this DC level

APPEARANCE OF OBJECTS

Data to Define the Material (Object)

– Dimensions (Different representations from being a “Trailer” to how it looks in timeline)

– – Container (H=Fixed, W=Fixed, Length=53, 40, 24)

– – Container ON Timeline (H=Fixed, W Fixed, Length=Duration on Schedule)

– Color

– Labels / Graphics (eg JB Hunt as Text or Logo)

Data to Define the Capacity (Lane)

– Dimensions, Color of the Lane

– Segmenting (Schedule States, Occupied, Maintenance, Open)

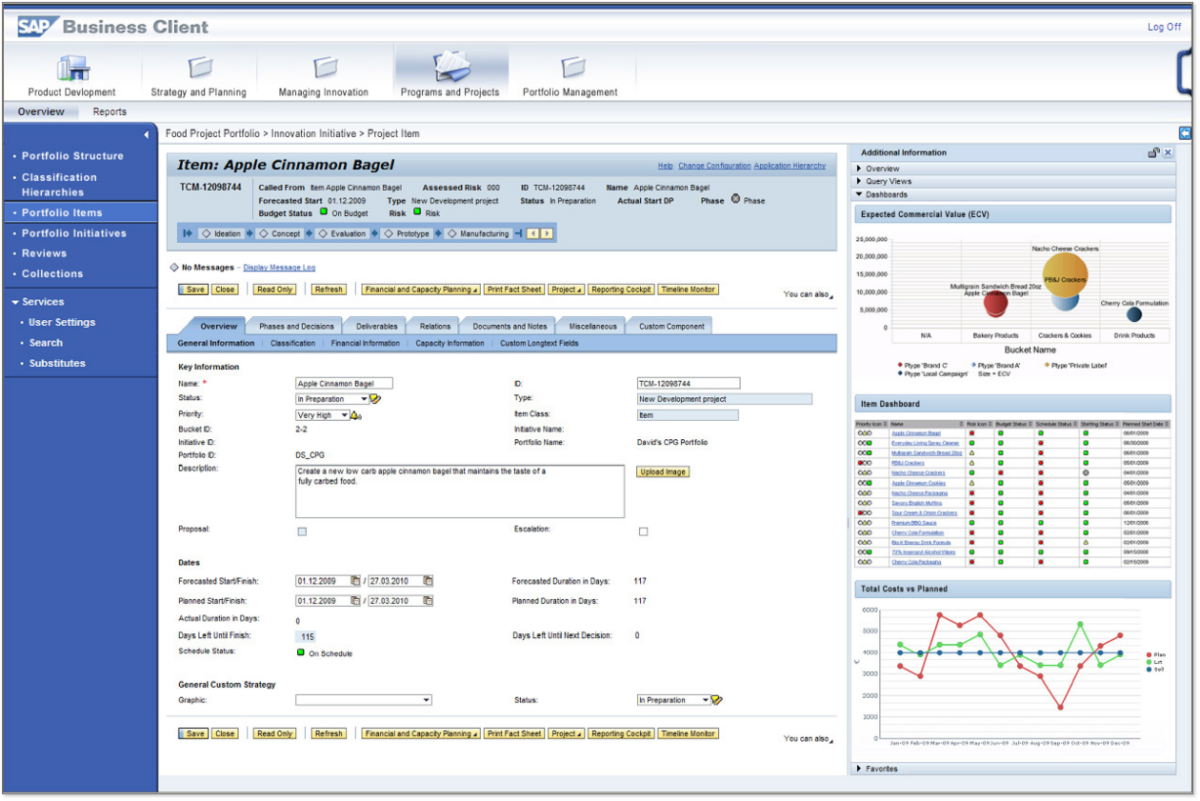

INTEGRATION

Writing to and from sample Data?

Primary Role: VP Product Management

Secondary Role(s): Designer

Business Driver(s):

Results & Benefits:

Time Range: 2014-2014

Class: Product